Casting is one of the most essential manufacturing processes, enabling the production of complex shapes using various metals, including aluminum. A crucial element in this process is sand cores, which serve as internal molds to create hollow spaces and intricate geometries within the final cast parts. The proper use of sand cores significantly impacts the quality, precision, and performance of the finished components.

The Role of Sand Cores in Casting

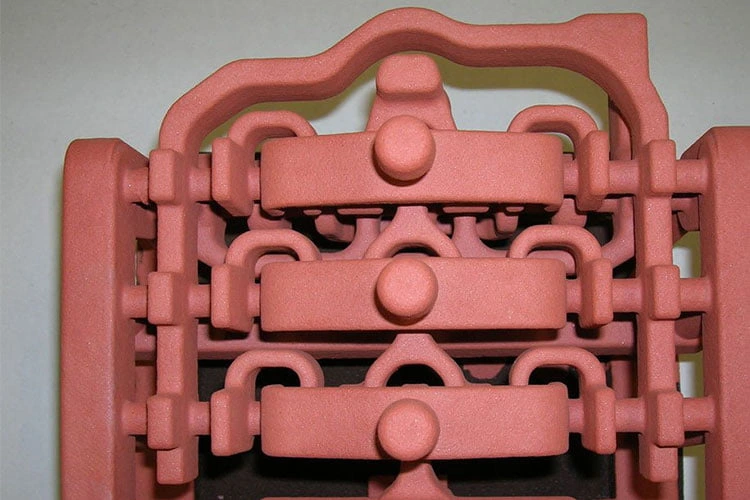

Sand cores are placed inside molds to shape internal cavities and structural features that would be difficult or impossible to machine. In aluminum casting, these cores not only help in reducing the weight of the component but also enhance its mechanical and thermal properties.

Properties and Advantages of Sand Cores

- Enables the production of complex geometries: Allows the creation of intricate designs that may not be achievable through other manufacturing techniques.

- High thermal resistance: Withstands the high temperatures of molten metal without deforming or collapsing.

- Easy removal after casting: Facilitates the extraction of sand without damaging the final part.

- Cost-effective production: Increases efficiency and reduces material waste.

Sand Core Manufacturing Methods

There are several methods for producing sand cores, each with its own advantages and applications:

1. Hot Box Method

In this process, a mixture of sand and thermosetting binder is poured into a heated metal core box. The heat triggers the binder reaction, solidifying the core within seconds. Advantages: High accuracy and excellent strength of the cores. Disadvantages: High energy consumption due to heating requirements.

2. Cold Box Method

This method involves mixing sand with special chemical binders and injecting it into a core box. A gaseous catalyst (such as amine) is then introduced to harden the binder. Advantages: Higher precision, faster production speed, and lower energy consumption. Disadvantages: Higher material costs compared to the hot box method.

3. Chemical (CO₂) Process

This method involves mixing sand with a sodium silicate binder, followed by passing carbon dioxide gas through the mixture to rapidly harden the core. Advantages: Simple and cost-effective process, no need for heating equipment. Disadvantages: Lower mechanical strength compared to other methods, making cores more brittle.

Impact of Sand Cores on Casting Quality

Optimal use of sand cores leads to significant improvements in the final casting quality:

- Enhanced dimensional accuracy: Minimizes deformations and unwanted shrinkage.

- Reduced casting defects: Lowers the risk of cracking, gas porosity, and material segregation.

- Improved mechanical strength and consistency: Produces homogeneous structures with fewer internal flaws.

Challenges and Limitations of Sand Core Usage

- Fragility: Cores may break during handling or the casting process.

- Advanced equipment requirements: Producing high-quality cores requires precision machinery and controlled conditions.

- Time and cost implications: The process can be time-consuming, especially for complex designs.

Future Trends and Innovations in Sand Core Technology

As technology advances, newer methods such as 3D sand printing are revolutionizing core-making processes. This approach enables rapid prototyping, greater design flexibility, and higher precision, paving the way for more efficient and sustainable manufacturing.

Conclusion

Sand cores play a vital role in aluminum casting, enabling the production of complex, high-quality parts. The choice of core-making method directly influences the final product’s accuracy, strength, and efficiency. With emerging technologies, the future of core-making is set to become even more advanced, driving improvements in speed, cost-effectiveness, and precision in the casting industry.